TriVision is a leading provider of advanced vision technology solutions, specializing in automated inspection systems for quality assurance. A core area of their expertise is label inspection, a critical aspect of modern production processes. By ensuring the accuracy and integrity of labels, TriVision’s label inspection help businesses maintain high standards, comply with regulations, and safeguard their brand reputation.

Cutting-Edge Label Inspection Technology

TriVision’s label inspection systems utilize state-of-the-art technology to deliver accurate and reliable results.

High-resolution cameras: These systems capture detailed images of every label, enabling precise analysis and defect detection.

Real-time processing: Advanced software evaluates labels instantly, ensuring that issues are identified and addressed without delay.

AI and machine learning integration: With the use of artificial intelligence, the systems continuously improve their inspection accuracy and adapt to changes in label designs or materials.

Key Features of Label Inspection

TriVision’s label inspection solutions offer comprehensive functionality to address a wide range of quality control needs.

Text and graphic accuracy: Ensures that printed text and logos are clear, correctly positioned, and free of errors.

Barcode verification: Checks the readability and validity of barcodes, crucial for supply chain tracking and retail scanning.

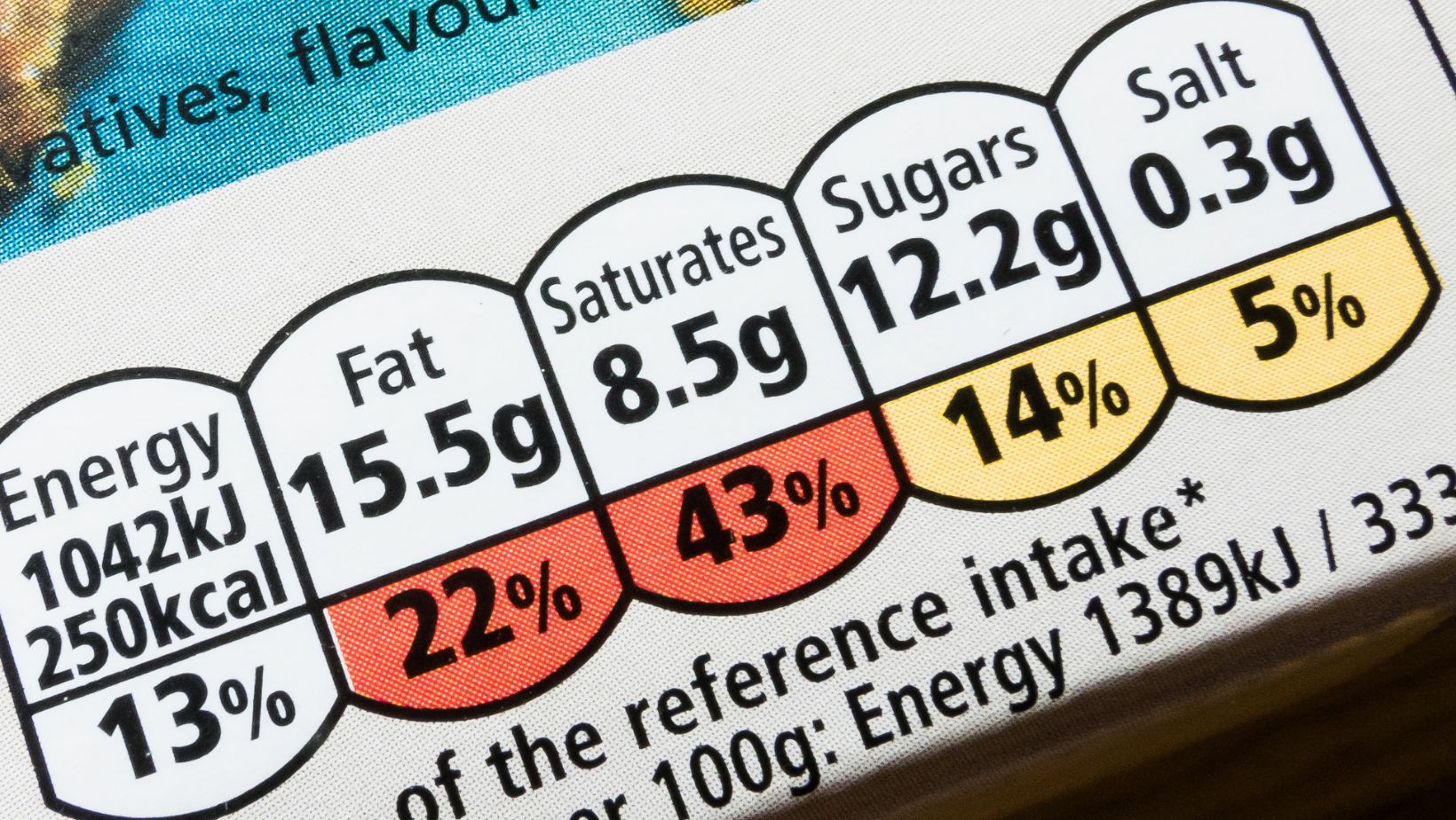

Compliance checks: Verifies that all regulatory information, such as expiration dates or allergen warnings, is present and accurate.

Alignment and positioning: Identifies labels that are misaligned or improperly placed on the packaging.

Surface quality inspection: Detects scratches, smudges, or other defects that compromise label appearance.

Advantages of TriVision’s Label Inspection Systems

Implementing TriVision’s label inspection technology offers significant benefits for manufacturers across industries.

Enhanced product quality: Automated inspection ensures that all products meet the required standards before reaching the market.

Increased efficiency: The systems reduce the need for manual checks, streamlining production lines and minimizing delays.

Regulatory compliance: TriVision’s solutions help companies adhere to industry standards, avoiding costly fines or recalls.

Cost reduction: Early detection of labeling errors minimizes waste and prevents expensive rework.

Industry-Specific Solutions

TriVision provides tailored label inspection systems that cater to the specific requirements of various industries, such as food and beverage, pharmaceuticals, and consumer goods. These customizable solutions ensure compatibility with different label types, sizes, and materials, enabling precise inspection in every scenario.

Conclusion

TriVision’s label inspection systems represent the pinnacle of quality assurance technology.

With their advanced features, real-time processing, and adaptability, these systems ensure that businesses can consistently deliver high-quality, accurately labeled products.